Carl Stahl Craftman

About Carl Stahl Craftman

Carl Stahl Craftsman Enterprises Pvt. Ltd. is a joint venture between Carl Stahl GmbH (Germany) and Craftsman Automation (India). With over a decade of innovation and engineering expertise, the company delivers high-performance material handling systems including Electric Wire Rope Hoists, EOT Cranes, Jib Cranes, and custom-built solutions. Their offerings are engineered for precision, safety, and reliability across various industries such as automotive, steel, and heavy machinery.

Products We Offer

Electric Chain Hoist

Get better lifting efficiency without worrying about load limits with Carlstahl Craftsman’s Electric Chain Hoists. Each hoist comes equipped with built-in overload protection and variable speed control, so your operators stay safe and your lifts stay precise, even with frequent use. As the trusted and most popular Electric Chain Hoist Manufacturers, we are known for delivering exceptional quality hoists and crane systems that enhance your safety and productivity while making sure only minimal maintenance is required. Our Electric Hoists let your team lift heavy equipment with the push of a button - no strain, no delays, just smooth operation. If you are going to lift 250 kg of equipment or 5 tonnes, our Electric Chain Hoist Series are compact, powerful and made to lift the weight and move with you. Used across automotive assembly lines, warehousing facilities, and steel manufacturing units, our hoists help reduce downtime, prevent manual injuries, and increase throughput, without needing layout redesigns.

E-Series Electric Chain Hoist

Incorporating a dependable overload prevention system, our Electric Chain Hoists prioritize safety. The strategic placement of the brake after the slip clutch ensures the highest level of safety while allowing for precise and straightforward adjustments. Our extensive product range spans from 250 to 5000 kgs, featuring lifting speeds ranging up to 10/2.5 m/min. Additionally, the Variable Frequency Drive facilitates the programming of lifting speed and ramp, providing flexibility and control.

Standard Specifications

| Capacity Range (Tons) | 0.25t to 5t |

| Classification | FEM Class - 1m , 2m , 3m , 4m |

| Lifting Speed | 10/2.5 & 5/1.2 m/min |

| Cross Travel Speed | 25/6 m/min |

| Power Supply | 3 Phase, 380 – 415 V, 50Hz |

| Control | 24 Volts , 50 Hz, (Contactor / VFD) |

| Chain | BS EN 818-7 |

| Brake | Electromagnetic Brake with Double Side Brake Lining |

| Chain Falls | Single chain fall & Double Chain Fall |

| Protection | Hoist – IP54, Pendant – IP65 |

| Safety Features | Overload & Over Travel Protection, Motor Temperature Control, Emergency Stop |

| Operating Conditions | -10°c to 45°c |

Features

- CE Certified

- Dual speed upto 10/2.5 m/min & customized solutions with single speed available for selected models.

- Dust and moisture protected as per IP55.

- Heavy Duty Plug-In Connections

- Powder coated exteriors for superior durability

- Controlled Starting Current

- Overload Protection

- Improved Power Factor & Lower Energy Consumption

- Equipped with Advanced Contactor Control System

- Variable Frequency Drive for smooth operation.

- Surface Hardened chain guarantees a long service life

- Ease in serviceability and availability of spares.

E-Series Models

| MODEL NO | CAPACITY | STATIONARY | PUSH PULL TROLLEY | MOTORIZED TROLLEY | CONTACTOR | VFD |

| ES 2 | ≤ 250 | ✔ | ✔ | ✔ | ✔ | ✖ |

| ES 3 | 500 ≤ 1000 | ✔ | ✔ | ✔ | ✔ | ✔ |

| ES 4 | 1000 ≤ 2000 | ✔ | ✔ | ✔ | ✔ | ✔ |

| ES 5 | 1600 ≤ 3200 | ✔ | ✔ | ✔ | ✔ | ✔ |

D-Series Electric Chain Hoist

Featuring a lightweight aluminum housing, heat-treated gears, and an overload clutch, our Electric Chain Hoists guarantee a seamless transmission. The Hoist's chain adheres to the BS-EN 818-7 standard, and its distinctive technology significantly enhances fatigue and wear resistance. Our comprehensive product range spans from 250 to 5000 kgs, offering lifting speeds ranging up to 8/2 m/min.

Standard Specifications

| Capacity Range (Tons) | 0.25t to 3.2t |

| Classification | FEM Class - 1m , 2m , 3m , 4m |

| Lifting Speed | 8/2 & 4/1 m/min |

| Cross Travel Speed | 25/6 m/min |

| Power Supply | 3 Phase, 380 – 415 V, 50Hz |

| Control | 24 Volts , 50 Hz, (Contactor) |

| Chain | BS EN 818-7 |

| Brake | Electromagnetic Brake with Double Side Brake Lining |

| Chain Falls | Single chain fall & Double Chain Fall |

| Protection | Hoist – IP55, Pendant – IP65 |

| Safety Features | Overload & Over Travel Protection, Motor Temperature Control, Emergency Stop |

| Operating Conditions | -10°c to 45°c |

Features

- Lightweight aluminium housing makes installation easier and reduces strain during setup or relocation.

- Durable, heat-treated gears that keep the hoist from daily wear and breakdowns.

- A built-in mechanical overload clutch for protection.

- BS-EN 818-7 certified chain can resist fatigue and wear.

- Dual-speed lifting (up to 8/2 m/min) gives you the control to move quickly or slow down.

- Torque adjustment make working and training user-friendly.

- IP55 protection keeps out dust and moisture.

- Quick plug-in connectors make installation and service simple.

- Surface-hardened chain guarantees a long service life.

- Maintenance-free design for trouble-free performance.

- Disc-type electromagnetic brake system for steady operation and long life.

- Powder-coated exteriors that keep the surface smooth and reduce wear & tear

D-Series Models

| MODEL NO | CAPACITY | STATIONARY | PUSH PULL TROLLEY | MOTORIZED TROLLEY | CONTACTOR | VFD |

| CA2010 | 1000 ≤ 2000 | ✔ | ✔ | ✔ | ✔ | ✖ |

| CA3216 | 1600 ≤ 3200 | ✔ | ✔ | ✔ | ✔ | ✖ |

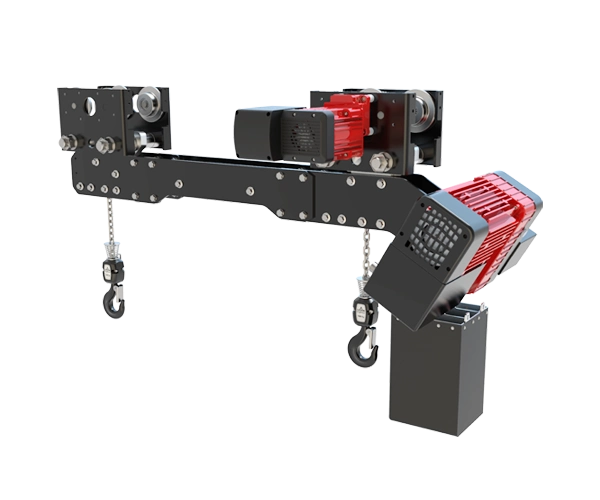

Twin Hook Electric Chain Hoist

Electric Chain Hoists with Twin Hooks feature a single operating motor and gearbox, making them ideal for lifting applications that demand two lifting points, especially for wide loads or when maintaining level lifting in a synchronised manner is essential. These Twin Hook Electric Chain Hoist are known for their simplicity, reliability, and smooth operation. Each hoist is designed with specific hook centers tailored to suit the particular application. The Dual Hook Electric Chain Hoist is compact in size, ensuring efficient use of space and a streamlined hook approach.

Standard Specifications

| Capacity Range (Kg) | 2x500 to 2x1600 |

| Classification | FEM Class - 2m |

| Lifting Speed | 8/2 & 4/1 m/min |

| Cross Travel Speed | 25/6 m/min |

| Power Supply | 3 Phase, 380 – 415 V, 50Hz |

| Control | 24 Volts , 50 Hz,(Contactor) |

| Chain | BS EN 818-7 |

| Brake | Electromagnetic Brake with Double Side Brake Lining |

| Chain Falls | Single chain fall & Double Chain Fall |

| Protection | Hoist – IP55, Pendant – IP65 |

| Safety Features | Overload & Over Travel Protection, Motor Temperature Control, Emergency Stop |

| Operating Conditions | -10°c to 45°c |

Features

- Our Chain Hoists are CE certified for safety, so your team can operate with confidence.

- IP55-rated protection shields against dust and moisture — perfect for real-world factory conditions.

- Dual-speed control allows fast movement when speed matters, and slow precision when alignment is critical.

- Automatic overload protection prevents unsafe lifts before they become a problem.

- A hard powder-coated enclosure will not wear out, corrode, or get damaged under tough shop conditions.

- Using standard electrical components means repairs can be done easily, restoring the unit to service while keeping downtime to a minimum.

- The fully mechanical slipping clutch provides overload protection, giving you a backup plan to prevent sudden equipment failures.

- Need height? How about up to 12 metres with heavy loads - more than enough for tall space or deep-pit applications.

- Each Dual-Hook Chain Hoist operates on its own sprocket, giving you a smoother run while reducing wear and increasing chain life.

- With the rotary limit switches, you can position the hook where you want, it will stop at the engagement point with no over-travel and no stress on the equipment.

Twin Hook Models

| MODEL NO | CAPACITY (Kg) | LIFTING SPEED (m/mm) | FALL | CLASS OF DUTY | MOTOR POWER (Kw) | CHAIN SIZE | HOOK CENTER DISTANCE (mm) |

| CA 2010T | 2x500 | 8/12 | 1 | 2m / M5 | 1.5/0.37 | 7x21 | 1000-4000 |

| 2x1000 | 4/1 | 2 | |||||

| CA 3216T | 2x800 | 8/12 | 1 | 2.4/0.6 | 9x27 | ||

| 2x1600 | 4/1 | 2 |

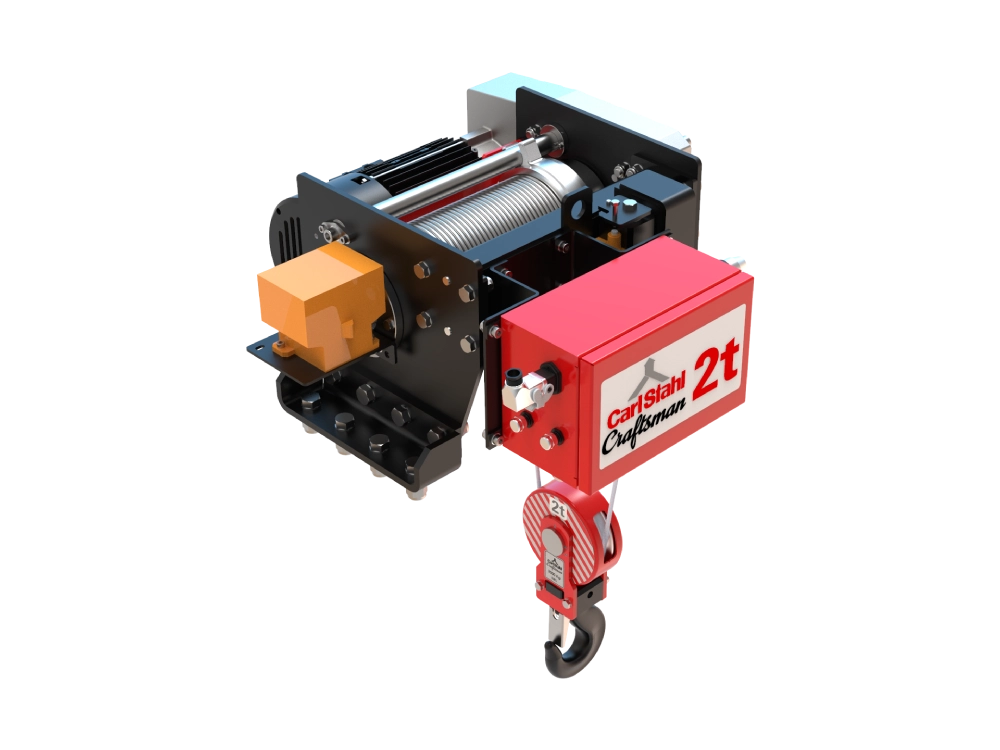

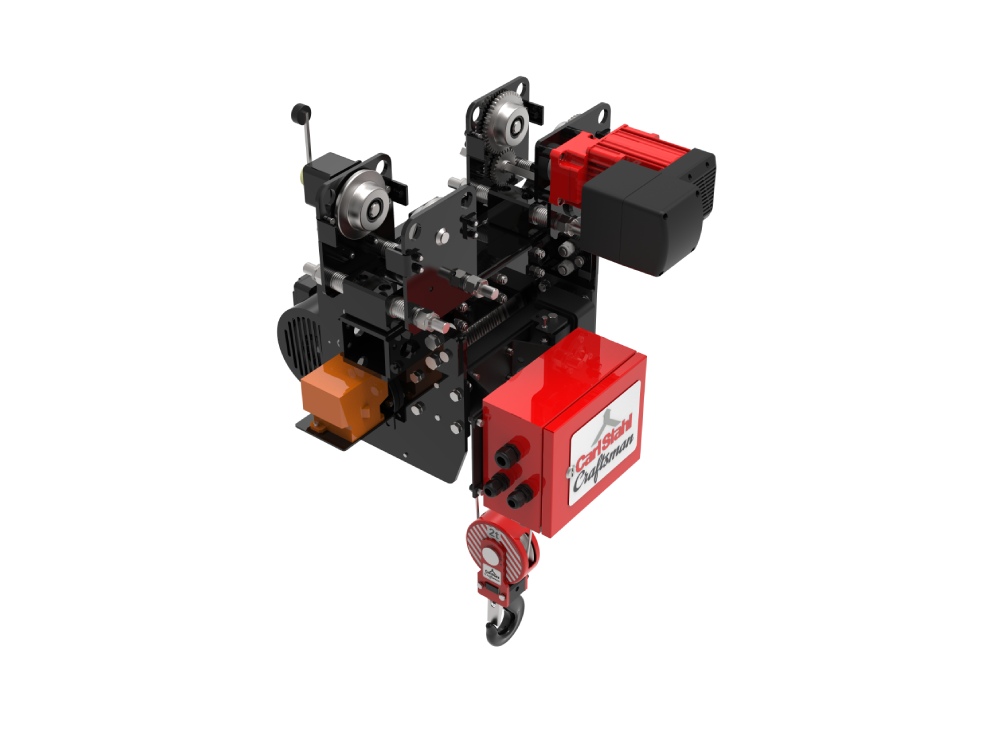

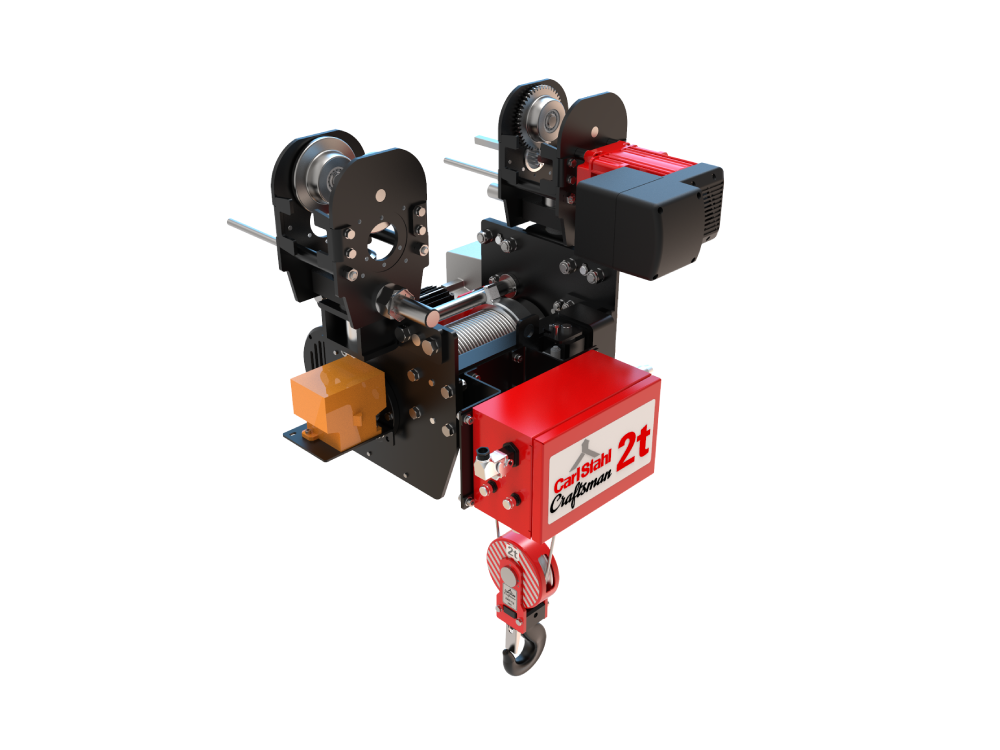

Electric Wire Rope Hoist

Are you looking for a hoist that actually doesn’t halt your production, breaks down often, or costs too much on maintenance? Get reliable heavy-duty lifts while reducing wear & tear and minimising the risk of equipment or load damage with our Carl Stahl Craftsman’s Electric Wire Rope Hoist. Whether you’re lifting 500 kg or 150 tonnes, our Electric Wire Rope Hoists are built for smooth, safe, and reliable operation, with the kind of performance that keeps your floor moving efficiently and quickly. The low maintenance needs, modular structure and enhanced safety features are what make Carlstahl Craftsman the leading Electric Wire Rope Hoist Manufacturers in India. And this can help you solve your lifting problems instantly.

Fixed Hoists

Craftsman's Fixed Hoists are reliable and adaptable solutions for diverse lifting applicationsThe design of our system is characterized by its compactness and an effective hook approach, ensuring efficiency in various lifting scenarios. Adhering to the M5 duty standard, the working group emphasizes reliability and high-performance operation. With dual lifting speed capabilities, the system offers flexibility in handling different loads with precision. The mounting configuration is facilitated through foot mounting, providing a fixed and stable foundation. This integrated design approach, combined with standardization in performance features, underscores the system's commitment to delivering reliable and adaptable solutions for diverse lifting applications.

Standard Specifications

| Capacity Range (Tons) | 0.5t to 1.6t |

| Classification | FEM 2m |

| Lifting Speed (m/min) | 10/2.5 , 5/1.25 ... ; Contactor Controlled |

| Travel Speed (m/min) | 25/6; Contactor Controlled |

| Power Supply | 415Volts, 3 Phase, 50 Hz, AC Supply |

| Control Supply | 48 Volts, 50 Hz, AC Supply Contactor Controlled |

| Ambient Temp.(°C) | 50°C Max |

| Application | Indoor |

| Thermal Insulation Class | F-Class |

| Motor Enclosure | IP 54 |

| Brake Type | Electromagnetic Disc Brake - DC |

| Hook | DIN 15400 |

| Rope Drum | Seamless pipe rope drum grooved as per DIN 15061 |

Features

- Modular in construction with flexibility on falls interchange (4/1,2/1).

- Light weight and comparably less headroom.

- Forged hooks according to DIN standards.

- Flanged wheels to guide the runway beam.

- Travel machinery directly drives the wheels.

- Acceleration and deceleration by inverters to increase the life span of the components.

Fixed Hoist Models

| Model | Working Load (Tons) | Lift Height (m) | Reeving | Speed (m/mm) | FEM |

| CRU 0.5 | 0.5t | 6, 9, 12, 18, 24 | 2/1 | 2.5/10 | 2M |

| CRU 01 | 1t | 1.25/5 | |||

| CRU 02 | 1.6t |

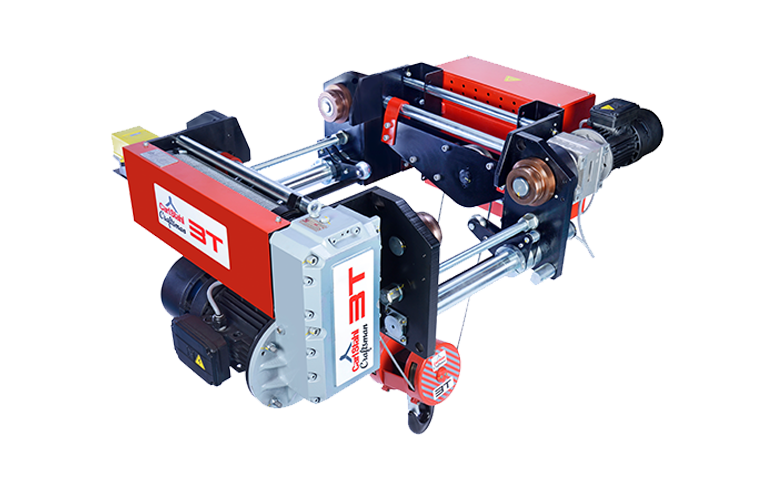

Dual Crab Hoist

The design of our system features the integration of two independent hoists within a shared frame, emphasizing a cohesive and efficient configuration.Operating under the M5 duty standard, the working group ensures a reliable and high-performance functionality. Additionally, the lifting speed is enhanced through the incorporation of frequency inverters for both lifting and cross-travel movements, providing precise control and adaptability to various operational requirements. This thoughtful design approach, coupled with standardized performance features, underscores the system's commitment to optimal functionality and flexibility in diverse lifting scenarios.

Standard Specifications

| Capacity Range (Tons) | 10t/5t, 16t/7.5t, 16t/10t |

| Classification | FEM 2m , 3m , 4m |

| Lifting Speed(m/min) | 1~4, 1.2~4.7, 1.2~5, 2.5~10... ; Frequency Controlled |

| Travel Speed(m/min) | 5~20; Freqency Controlled |

| Power Supply | 415Volts, 3 Phase, 50 Hz, AC Supply |

| Control Supply | 24 Volts, 50 Hz, DC Supply Frequency Controlled |

| Ambient Temp. (°C) | 50°C Max |

| Application | Indoor |

| Thermal Insulation Class | F-Class |

| Motor Enclosure | IP 54 |

| Brake Type | Electromagnetic Disc Brake - AC |

| Hook | DIN 15400 |

| Rope Drum | Seamless pipe rope drum grooved as per DIN 15061 |

Features

- Durable Rope Guide ensures wire rope tightly in drum.

- DIN Hook with 360° rotation.

- In build Hoist Panel with plug and socket connections.

- Pendant unit controls two hoists for combined operation or for one hoist operation.

Safety

- Rope safety as recommended by FEM norms.

- When using both the Hoist at same time, the total load capacity lifted should not exceed the minimum lifting capacity in the common frame.

- E.g.: In 16T/10T model the load should not exceed the 10T.

Technical Advantages

- Design: Two independent hoists are mounted in common frame.

- Lifting Speed: Frequency inverters for lifting and cross travel movements.

- Working Group: Standard with M5 duty.

Dual Crab Models

| Model | Working Load (Tons) | Track Gauge (mm) | Lift Height (m) | Reeving | Speed (m/mm) | FEM |

| CLHD 10/5 | 10t | 1250 | 6, 8, 12 | 4/1 | 1.2~4.7 | 2M |

| 1400 | ||||||

| 1800 | ||||||

| CLHD 16/7.5 | 16t | |||||

| 1400 | ||||||

| 1800 | ||||||

| CLHD 16/10 | 16t | 1400 | ||||

| 1800 | ||||||

| CLHD 20/5 | ||||||

| CLHD 20/10 | ||||||

| CLHD 30/10 | ||||||

| CLHD 40/15 | ||||||

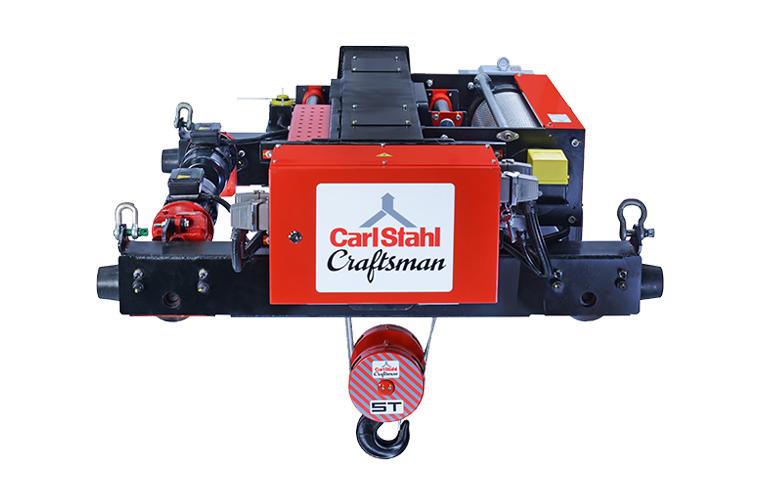

Double Girder Crab Hoist

The double rail crab adheres to standard track gauges of 1250, 1400, 1800, 2240 and 2800mm, which can suffice for Replacement of Existing Old Crabs.Engineered to meet the FEM duty cycle, the end carriage is specifically designed to accommodate the standard wheel block with double-side mounting. Dual cross-travel drives are provided as a standard feature for the cross-travel movement of the trolley across R-Series crab hoist models. The modular construction and use of standard parts, such as wheel blocks, reduce the risk during assembly, ensuring a reliable and efficient system.

Standard Specifications

| Capacity Range (Tons) | 5t to 63t |

| Classification | FEM 2m , 3m , 4m |

| Lifting Speed(m/min) | 0.6~5 M/Min Frequency Controlled |

| Travel Speed(m/min) | 5~20; Freqency Controlled |

| Power Supply | 415Volts, 3 Phase, 50 Hz, AC Supply |

| Control Supply | 24 Volts, 50 Hz, DC Supply Frequency Controlled |

| Ambient Temp. (°C) | 50°C Max |

| Application | Indoor |

| Thermal Insulation Class | F-Class |

| Motor Enclosure | IP 54 |

| Brake Type | Electromagnetic Disc Brake - DC |

| Hook | DIN 15400 |

| Rope Drum | Seamless pipe rope drum grooved as per DIN 15061 |

Features

- Modular in construction with flexibility on falls interchange (4/1), (6/1).

- Light weight and comparably less headroom.

- Two Travel machinery directly drives the wheels, avoid the connection failure and transmission loss.

- Acceleration and deceleration by inverters to increase the life span of the components.

Safety

- Rope safety factor >= 5

- Motor over heating protection with thermistor.

- Double limit switch for up and down travel movement.

- Precise and accurate closed loop overload protection system (via.) VFD.

- Reliable load clamping by safety latch.

Technical Advantages

- Lifting height : 6m, 8m, 9m, 12m, & 16m.

- Double rail crab standard track gauges of 1250, 1400, 1800, 2240 mm.

- Designed to meet the FEM duty cycle.

- End carriage is designed to suit standard Wheel block with double side mounting.

- Dual cross travel drives are made as a standard supply for cross travel movement of trolley, across R-Series crab hoist models.

- Modular in construction and standard parts like wheel blocks are used to reduce the risk of assembly.

Double Girder Crab Models

| Model | Working Load (Tons) | Track Gauge (mm) | Lift Height (m) | Reeving | Speed (m/mm) | FEM |

| CLHD 05 | 5t | 1250 | 6, 9, 12 | 4/1 | 1 ~4 | 2M |

| 1400 | ||||||

| CLHD 10 | 7.5t | 1250 | 1.2~4.7 | |||

| 1400 | ||||||

| 1800 | ||||||

| 10t | 1250 | 1.2~4.7 | ||||

| 1400 | ||||||

| 1800 | ||||||

| 15t | 1400 | 6, 8, 12 | 6/1 | 0.8~3 | ||

| 1800 | ||||||

| 2240 | ||||||

| CLHD 16 | 16t | 1400 | 8, 12, 16, 20. 24, 30 | 4/1 | 1.2~4.7 | 2M |

| 1800 | ||||||

| 2240 | ||||||

| 25t | 1800 | 8, 10, 12, 16, 20 | 6/1 | 0.75~3 | ||

| 2240 | ||||||

| 2800 | ||||||

| 3200 | ||||||

| CR20 | 30 | 1800 | 6.7, 10, 13.3 | 6/1 | 0.6 ~2.47 | 2M |

| 2240 | ||||||

| 2800 | ||||||

| CR20 | 32 | 1800 | ||||

| 2240 | ||||||

| 2800 | ||||||

| CR32 | 40 | 2240 | 8, 12, 16, 20, 24 | 4/1 | 0.9 ~3.7 | 2M |

| 2500 | ||||||

| 2800 | ||||||

| 3200 | ||||||

| 3800 | ||||||

| CR32 | 50 | 2500 | 8, 10.6, 13.3, 16 | 6/1 | 0.6 ~2.47 | 2M |

| 2800 | ||||||

| 3200 | ||||||

| 3800 | ||||||

| CR32 | 62 | 2500 | ||||

| 2800 | ||||||

| 3200 | ||||||

| 3800 |

Single Girder Chain Hoist

The compact modular design ensures optimal hook approach, adhering to FEM/DIN/ISO standards.Operational efficiency is enhanced by eliminating counterweights. All variants up to 15t , come with a standard supply of Duty Class ISO M5/FEM 2m. The flange width is easily adjustable through threaded screws and fasteners. Standard inclusion of frequency inverters in both lifting and cross-travel movements ensures increased longevity of mechanical components. Speed control via inverters allows for selectable speeds, providing precise handling and smooth movement.

Standard Specifications

| Capacity Range | 500 Kg to 10000 Kg |

| Classification | FEM 2m, 3m, 4m |

| Lifting Speed(m/min) | 1~10 M/Min (Frequency Controlled) |

| Travel Speed(m/min) | 5~20; Freqency Controlled 25/6; Contactor Controlled |

| Power Supply | 415Volts, 3 Phase, 50 Hz, AC Supply |

| Control Supply | 24 Volts, 50 Hz, DC Supply Frequency Controlled 48 Volts, 50 Hz, AC Supply Contactor Controlled |

| Ambient Temp. (°C) | 50°C Max |

| Application | Indoor |

| Thermal Insulation Class | F-Class |

| Motor Enclosure | IP 54 |

| Brake Type | Electromagnetic Disc Brake - AC/DC |

| Runway Beam | ISMB 100~600 (or) Plate (Width may vary) |

| Hook | DIN 15400 |

| Rope Drum | Seamless pipe rope drum grooved as per DIN 15061 |

Features

- Modular in construction with flexibility on falls interchange (4/1,2/1).

- Light weight and comparably less headroom.

- Forged hooks according to DIN standards.

- Flanged wheels to guide the runway beam.

- Travel machinery directly drives the wheels.

- Acceleration and deceleration by inverters to increase the life span of the components.

Safety

- Rope safety factor >= 5

- Motor over heating protection with thermistor.

- Double limit switch for up and down travel movement.

- Precise and accurate closed loop overload protection system (via.) VFD.

- Reliable load clamping by safety latch.

CLH Series Models

| Model NO | Working Load (Tons) | Lift Height (m) | Reeving | Speed (m/mm) | FEM |

| CLH 0.5 | 0.5T | 6, 9, 12, 18, 24 | 2/1 | 2.5~10 | 2M |

| CLH 01 | 1T | 1.25~5 | |||

| CLH 02 | 2T | ||||

| CLH 03 | 3T | 6, 9, 12 | 4/1 | ||

| CLH 05 | 5T | 1~4 | |||

| CLH 7.5 | 7.5T | 1.2~4.7 | |||

| CLH 10 | 10T | ||||

| CLH 10 | 15T | 6/1 | 0.8~3 |

Underslung Hoist - Straight Trolley

The design of our system is characterized by its compactness and efficient hook approach.We have achieved an optimized weight balance, eliminating the need for counterweights and contributing to a streamlined operational setup. The working group adheres to the M5 duty standard, ensuring reliability and performance. The dual lifting speed capability enhances versatility in handling various loads. The trolley is specifically designed for smooth movement along a straight path, adding to the overall efficiency and functionality of the system.

Standard Specifications

| Capacity Range (Tons) | 5t to 1.6t |

| Classification | FEM 2m |

| Lifting Speed(m/min) | 10/2.5, 5/1.25 ...; Contactor Controlled |

| Travel Speed(m/min) | 25/6; Contactor Controlled |

| Power Supply | 415Volts, 3 Phase, 50 Hz, AC Supply |

| Control Supply | 48 Volts, 50 Hz, AC Supply Contactor Controlled |

| Ambient Temp. (°C) | 50°C Max |

| Application | Indoor |

| Thermal Insulation Class | F-Class |

| Motor Enclosure | IP 54 |

| Brake Type | Electromagnetic Disc Brake - AC/DC |

| Runway Beam(mm) | ISMB 140 (or) Plate (Radius of Curvature - 1.5M) |

| Hook | DIN 15400 |

| Rope Drum | Seamless pipe rope drum grooved as per DIN 15061 |

Features

- Durable Rope Guide ensures wire rope tightly in drum.

- Trolley drive with integrated brake motor.

- DIN Hook with 360° rotation.

- In build Hoist Panel with plug and socket connections.

Safety

- Double limit switch for Up and Down Lifting.

- Mechanical overload protection.

- Safety Latch for Hook.

Underslung Hoist - Straight Trolley Models

| Model NO | Working Load (Tons) | Lift Height (m) | Reeving | Speed (m/mm) | FEM |

| CRU 0.5 | 0.5t | 6, 9, 12, 18, 24 | 2/1 | 2.5/10 | 2M |

| CRU 01 | 1t | 1.25/5 | |||

| CRU 02 | 2t |

Underslung Hoist - Articulated Trolley

Our system boasts a design characterized by its compactness and an effective hook approach.The weight balance has been meticulously optimized, eliminating the need for counterweights and contributing to a streamlined operational configuration. The working group adheres to the M5 duty standard, ensuring a reliable and high-performance operation. With dual lifting speed capabilities, our system offers versatility in handling various loads. The trolley is purposefully crafted for seamless movement along curved paths, enhancing the overall efficiency and adaptability of the system.

Standard Specifications

| Capacity Range (Tons) | 0.5t to 1.6t |

| Classification | FEM 2m |

| Lifting Speed(m/min) | 10/2.5 , 5/1.25 ... ; Contactor Controlled |

| Travel Speed(m/min) | 25/6; Contactor Controlled |

| Power Supply | 415Volts, 3 Phase, 50 Hz, AC Supply |

| Control Supply | 48 Volts, 50 Hz, AC Supply Contactor Controlled |

| Ambient Temp. (°C) | -10°C to 45°C |

| Application | Indoor |

| Thermal Insulation Class | F-Class |

| Motor Enclosure | IP 54 |

| Brake Type | Electromagnetic Disc Brake |

| Runway Beam (mm) | ISMB 140 (or) Plate (Radius of Curvature - 1.5M) |

| Hook | DIN 15400 |

| Rope Drum | Seamless pipe rope drum grooved as per DIN 15061 |

Features

- Durable Rope Guide ensures wire rope tightly in drum.

- Trolley drive with integrated brake motor.

- DIN Hook with 360° rotation.

- In build Hoist Panel with plug and socket connections.

Safety

- Double limit switch for Up and Down Lifting.

- Safety Latch for Hook.

- Mechanical overload protection.

Underslung Hoist - Articulated Trolley Models

| Model NO | Working Load (Tons) | Lift Height (m) | Reeving | Speed (m/mm) | FEM |

| CRU 0.5 | 0.5t | 6, 9, 12, 18, 24 | 2/1 | 2.5/10 | 2M |

| CRU 01 | 1t | 1.25/5 | |||

| CRU 02 | 1.6t |